B&L Chocolate

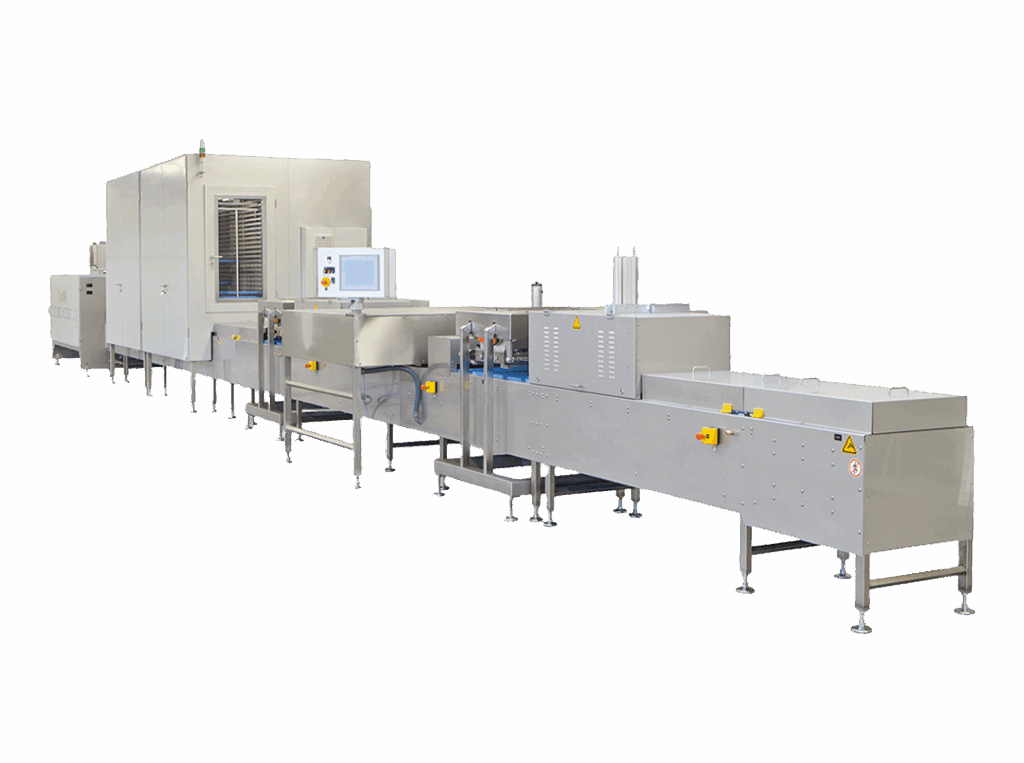

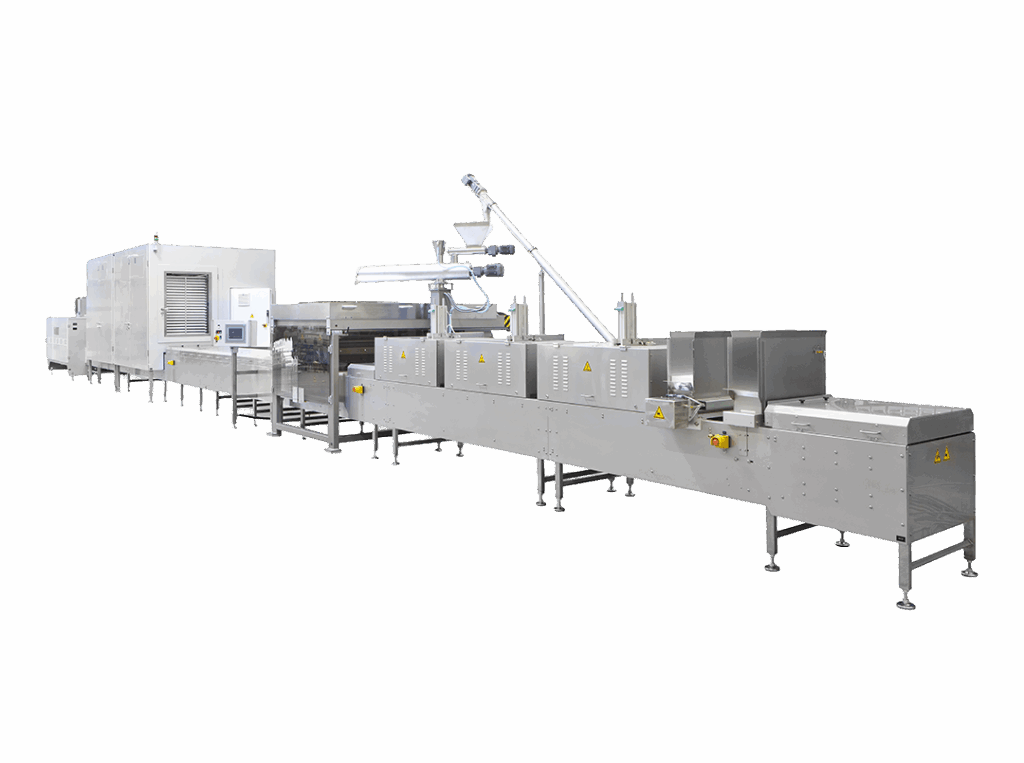

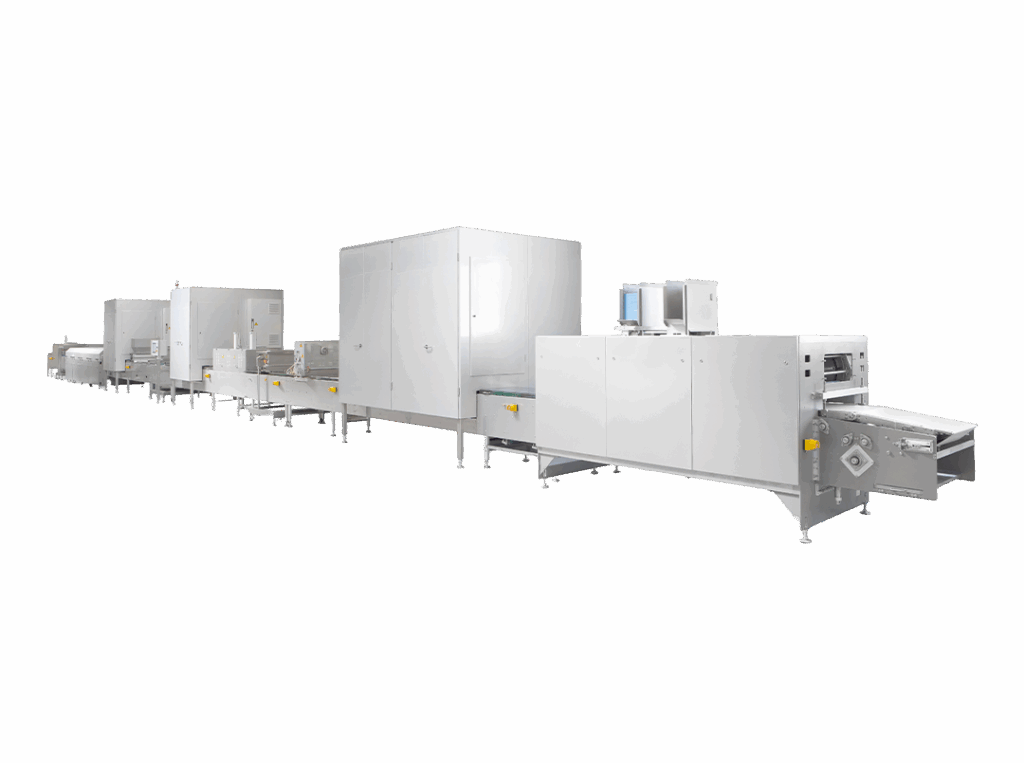

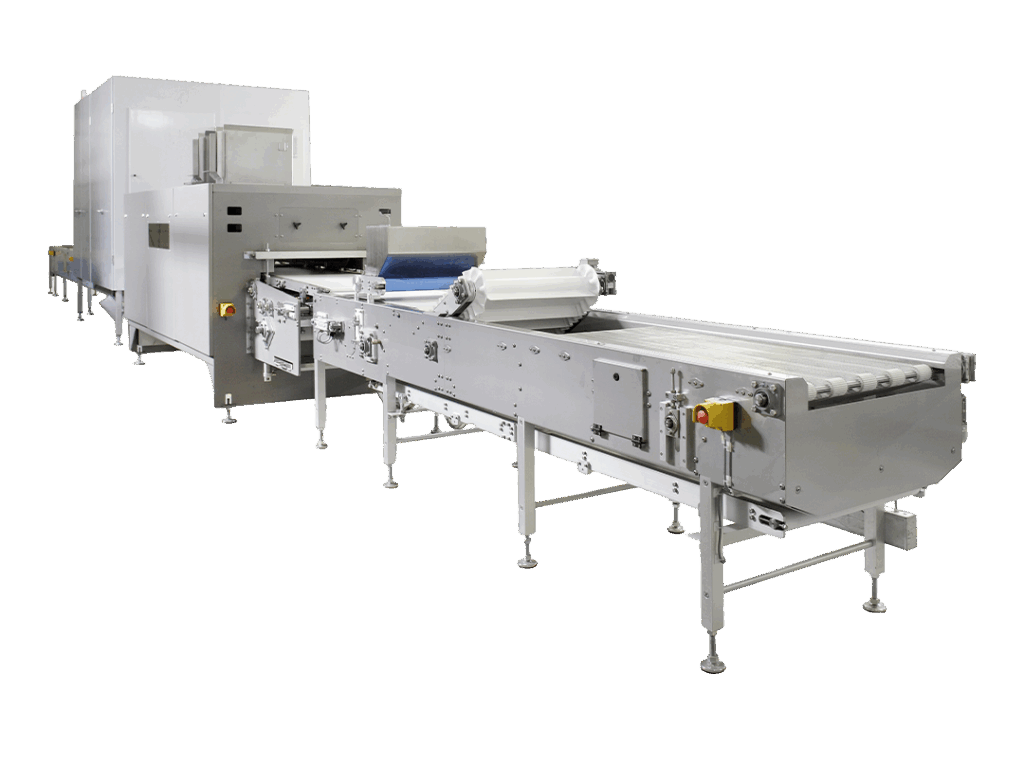

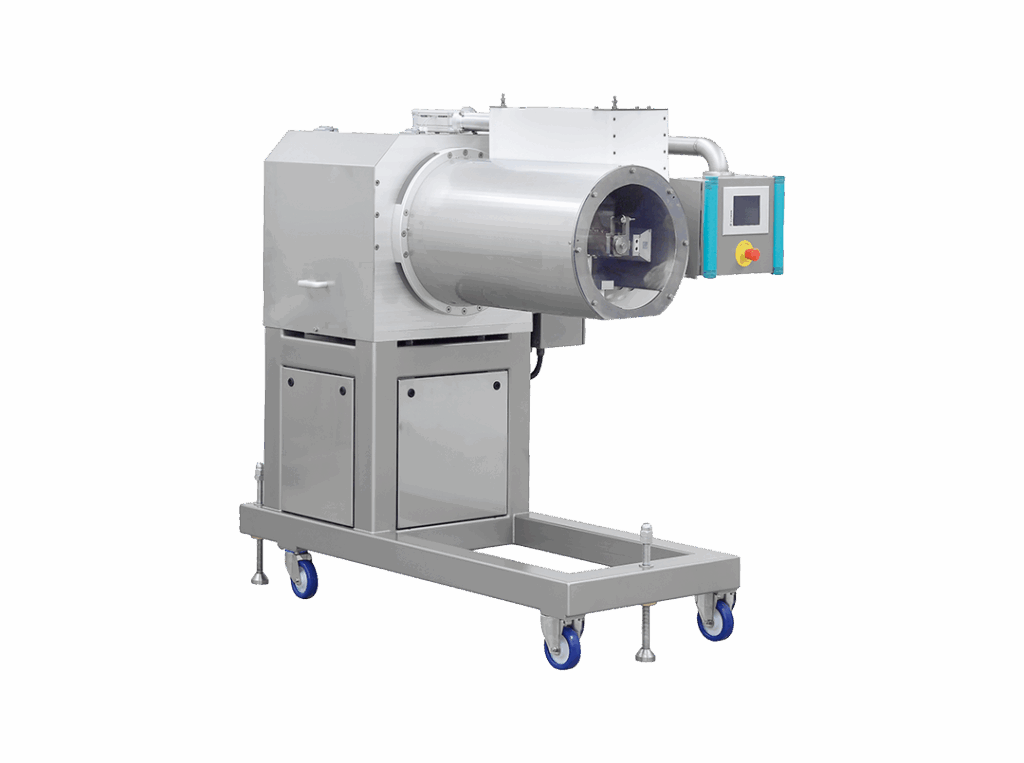

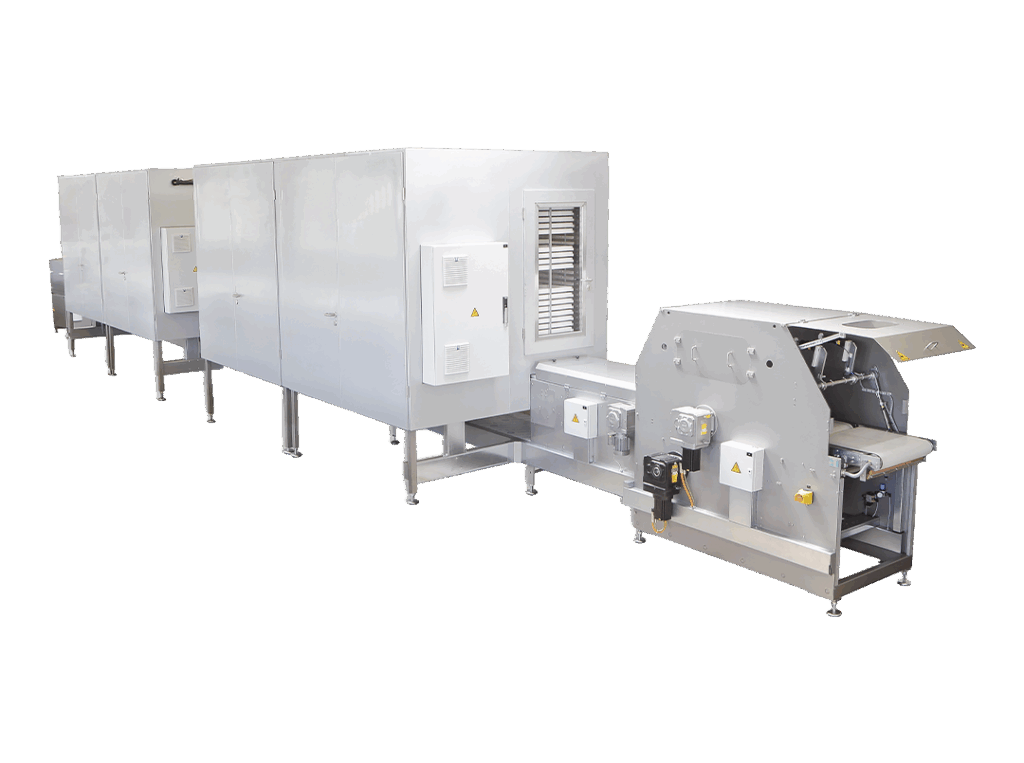

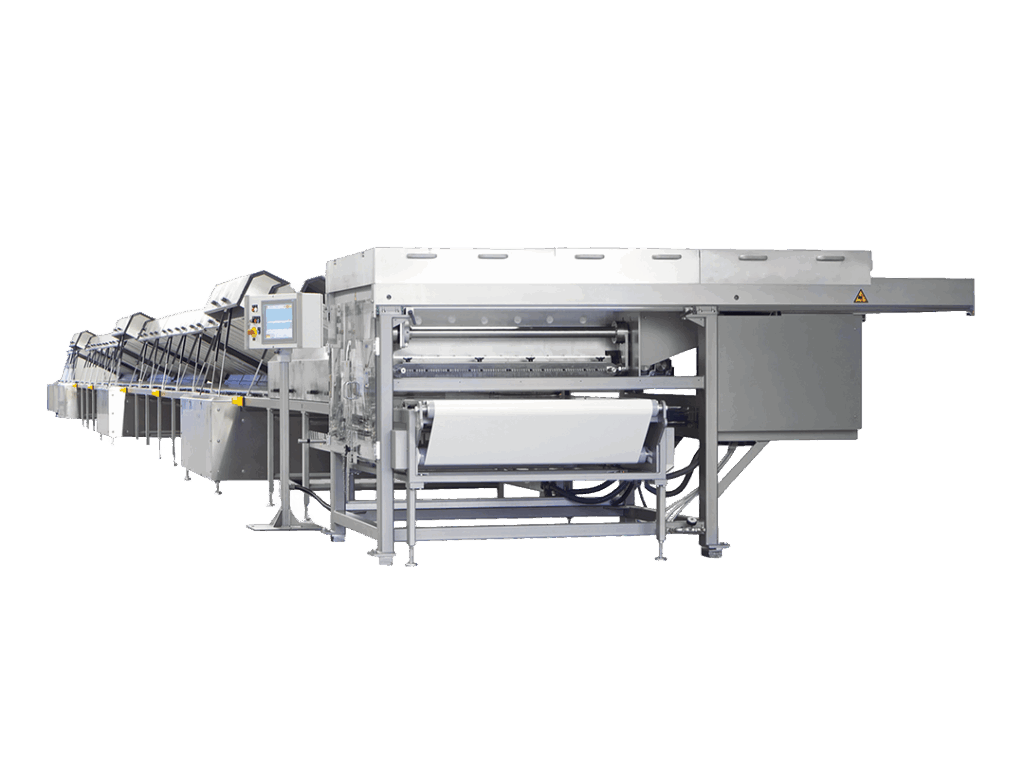

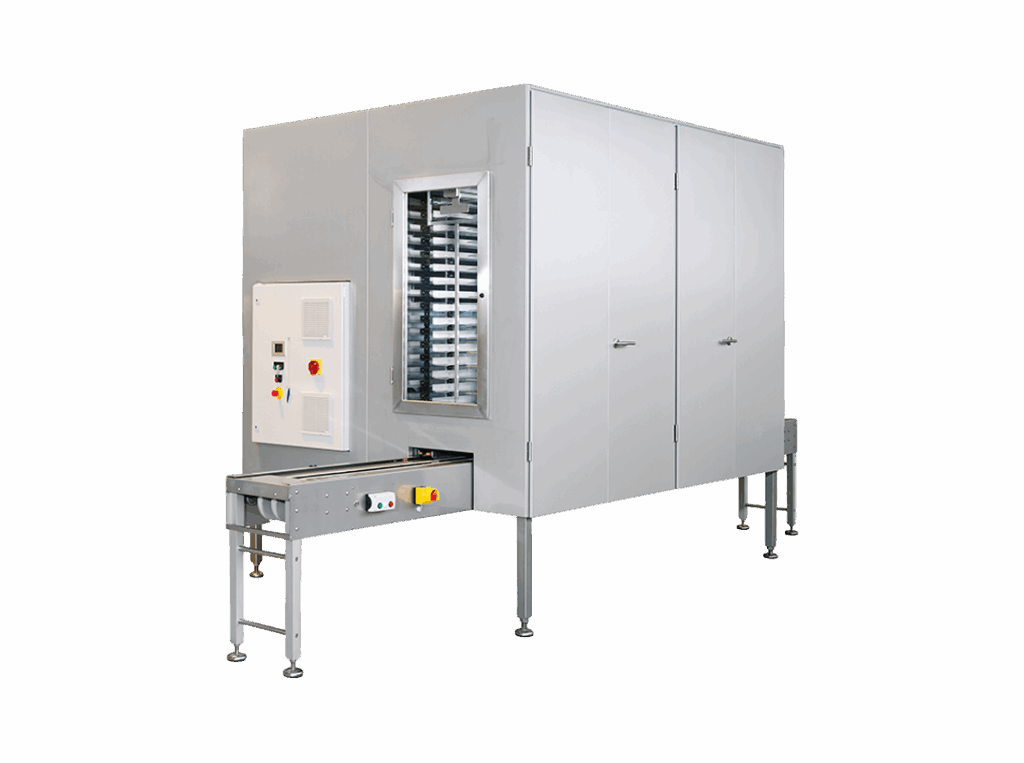

Processing excellence with TFT equipment

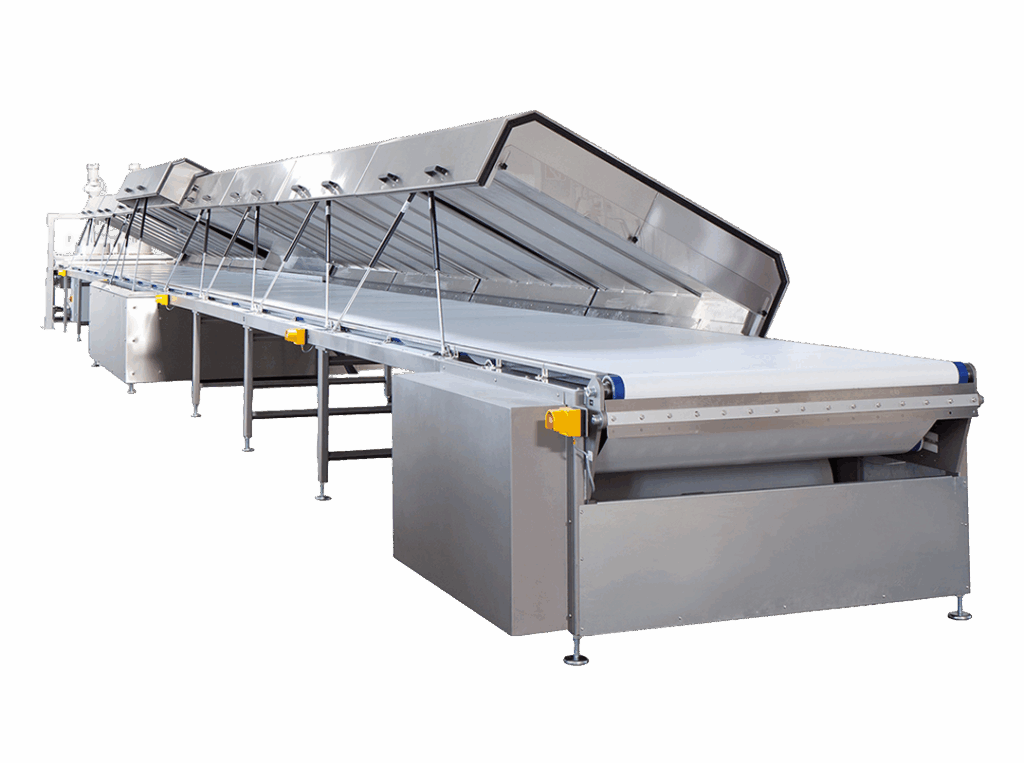

At B&L Chocolate, we partner with TFT to ensure the highest quality in our production process. TFT supplies advanced processing equipment essential for creating a variety of delicious fillings, such as nougat, caramel, jelly, ganache, and aerated creams.

TFT’s technology guarantees consistency, quality, and efficiency, helping us craft fillings that meet our high standards for taste and texture. From smooth ganache to fluffy creams, TFT’s equipment enables us to deliver the finest chocolate experience in every bite.