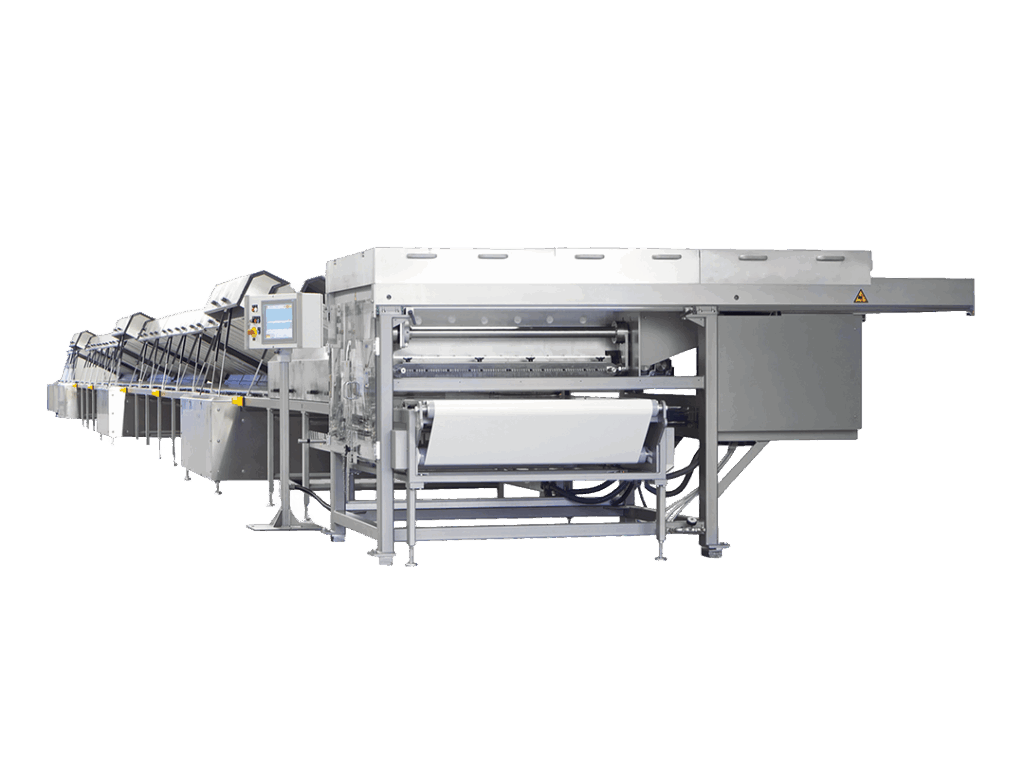

Drops/ button depositing

Due to their large surface area, chocolate and compound drops can easily be melted for further processing. Additionally these drops are easy to dose. This is also ideal for a bake-stable filling. They are produced on drop lines, which are a combination of a drop depositor and a cooling channel. BL Chocolate drop depositors offer exact dosing weights through their servo controlled piston stroke system. The cooling channel can be equipped with bottom water cooling. Radiation cooling, convection cooling or a combination of both can also be selected by the operator.